Description

The highest precision

Full repeatability and accuracy of performed details guaranteed by a solid structure and high-class control system.

Functional controls

Industrial control system for the comprehensive management of the machine and its key components.

High performance

The solid structure allows for aggressive machining while maintaining the precision of the details and their repeatability.

Przykłady zastosowania

Technical data

| Control system | Multi-axis real-time interpolator, with active trajectory forecasting, LAN communication, EtherCat, 2ms sampling time, optional RTCP tool end tracking, correction map, remote service access |

| Working area | X: 600 – 2100 mm Y: 900 – 6000 mm |

| Z axis range | 200 – 500 mm |

| Drive system | Omron servo drives with EtherCat protocol, X, Y helical slats hardened ground in accuracy class 6, Z axis ball screw with accuracy class 5 |

| Linear bearing | Trapezoidal rails, Bosch Rexroth 25 |

| Travel speed | Up to 80 m / min |

| Acceleration | up to 1G |

| Program resolution | up to 0,0001mm |

| Positioning accuracy | 0,01 mm |

| Gate drive | double-sided master / slave with gate angle correction |

| Electrospindles | 8 kW to 36 kW powered by an inverter |

| Tool taper | ISO30 or HSK63 ER32 |

| Maximum speed of the electro-spindle | 24,000 rpm (option 6,000, 40,000, 50,000) |

| Construction | Steel welded, ribbed, stress relieved, precision machined |

| Table type: | T-raster aluminum, solid aluminum, solid steel |

| Equipment options |

|

Gallery

Stable structure with the highest parameters

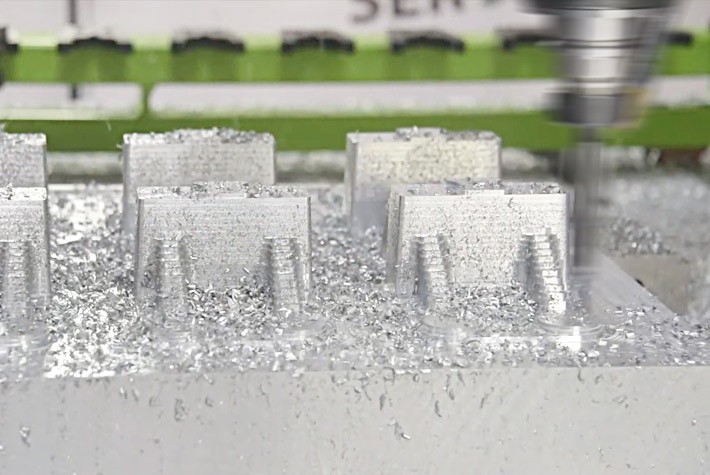

HardLine are professional, industrial machine tools designed for companies working in demanding materials. The massive structure based on the conceptual design of the PRO series machines is an excellent basis for the implementation of advanced technological solutions, and in combination with selected components from renowned manufacturers, it ensures high performance and long-term, reliable operation of the machine tool.

The suggested configuration is equipped with a table made of solid steel or aluminum, both for mechanical and vacuum clamping, which ensures the stabilization of elements, which is particularly important when working in hard materials requiring high machining precision.

Construction

The steel, welded and ribbed structure is characterized by the highest parameters, ensuring precise processing at high speeds and dynamics of movements. The bed and the running elements are subjected to the process of stress relief and machining on large-format milling centers, which ensures long-term stability and dimensional precision of the machine. Learn more about the construction »

Control

HardLine machine by their high efficiency and work dynamics to professional CNC control. The EtherCat communication protocol with a sampling time of less than 1ms enables ultra-fast two-way communication with key components. The smooth and precise operation of the machine tool is also influenced by the multi-axis real-time interpolator, which actively forecasts the motion path, minimizing the lag error also in the HPM and HSM machining modes. The operator’s comfort is also increased by the integrated CAD / CAM environment which allows for easy editing of files directly on the control unit. The structure of the G-code enables the individual design of cycles and operations, automating them according to the user’s preferences

Learn more about control »

Basic features of the Hardline series

- modern real-time control system

- dynamic trajectory analysis using the EtherCat protocol

- high vibration damping coefficient

- efficient processing of demanding materials

- precise table made of solid material

- effective tool cooling

- extensive equipment

- remote technical support

Dedicated materials

- metals

- composites (dibond, alucobond, etc.)

- plastics: polycarbonate, PVC, plexiglass, rubber, Teflon, polyamides, etc.

- solid wood, plywood, chipboards, MDF, OSB

The benefits of buying Seron machines

The advantages and capabilities of our devices are not all that you will get by choosing to work with us

Ask for na offer

Our advisers are at your disposal. Fill out the form below and contact us!