Description

A specialized machine

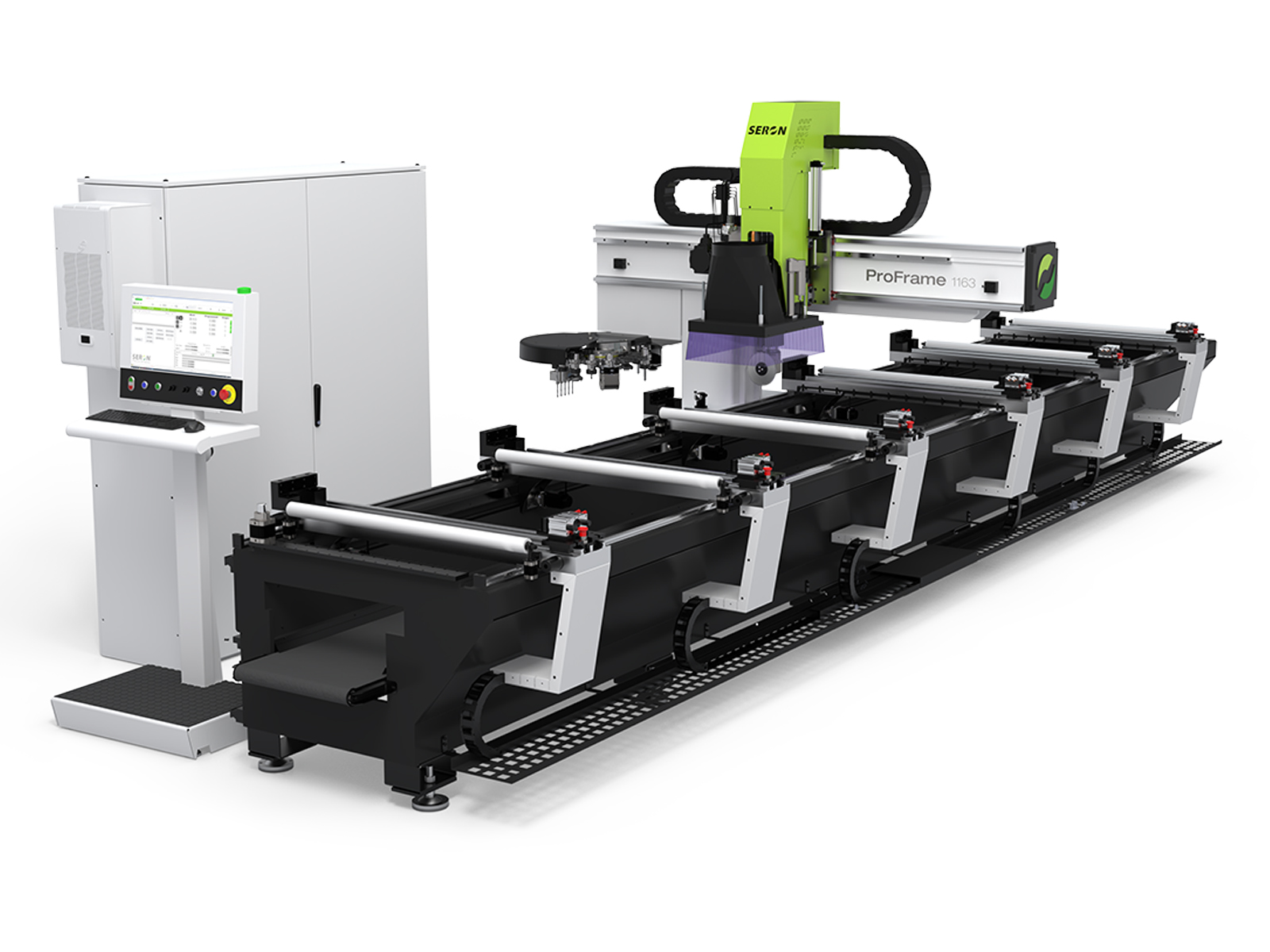

A specialized machining center designed for processing profiles.

Production automation

For serial and unit production.

Selected components

Machine are equipped only with the highest quality components, known and recognized on the market, guarantee reliability.

Technical data

| Control system | multi-axis real-time interpolator with active forecasting trajectory, LAN communication, EtherCat, sampling time below 2 ms, RTCP, remote service access |

|---|---|

| Working field | X: to 6300 mm Y: do 1100 mm |

| Z axis clearance | 200 – 400 mm |

| Drive system | Omron servo drives with EtherCat protocol, X, Y hardened helical strips ground in accuracy class 6, Z axis, ball screw in accuracy class 5 |

| Linear bearings | trapezoidal rails, Y axis, double guide size 35, X and Z axis double guide size 25 |

| Travel speed | to 60 m/min |

| Gate drive | unilateral |

| Software resolution | to 0,0001 mm |

| Positioning accuracy | 0,01 mm |

| Electrospindles | 12 kW to 25 kW powered by an inverter |

| Tool cone | HSKF63 |

| Maximum electrospindle revolutions | 24000 rpm (option 6 000, 40 000, 50 000) |

| Design | welded, ribbed, annealed, precision machined steel |

| Type of table | Cantilever, pneumatic vices |

| Equipment options |

|

Gallery

A solution designed for precision machining

profiles

The ProFrame machine was designed for flexibility and efficiency in production. The structure of the device is based on a welded, stress-relieved, ribbed steel structure. Equipped with a console table, designed to enable automatic and manual manipulation of beams, adjusting the appropriate spacing for a given production cycle. The beams can be mounted with vices, both automatic and manual, which ensures stable clamping of details. This solution makes it easier to place the material for processing and ensures the highest level of precision.

Design

The machine gate is based on one arm, which significantly facilitates access to the processed elements on the machining table. The use of such a structure has a positive effect on work ergonomics and translates into increased efficiency. The possibility of processing from many sides, including from the bottom, allows the implementation of various projects. The ProFrame Machining Center means not only precision in production, but also intuitive control. Dynamic servo drives enable quick positioning of the processing unit, reaching speeds of up to 60 m/min. Thanks to the use of a turret magazine in its design, the machine guarantees short tool change times, which translates into optimal machining cycles. Find out more about the structure »

Control

ProFrame series machines are equipped with an industrial control system. The EtherCat protocol enables fast two-way communication with key components, and a multi-axis, ultra-fast real-time interpolator minimizes tracking error. The integrated CAD/CAM environment facilitates the operator’s work by enabling file editing directly on the control unit. The use of absolute encoders eliminates the need to perform movement

axis reference, which increases precision and saves time. Additionally, remote service access allows you to monitor and maintain the machine at the highest level of performance, which makes it not only a work tool, but also an investment in long-term production success. Learn more about controls »

Basic features of the ProFrame Machining Center

- Compliant with Industry 4.0 management concept

- Advanced real-time control system

- Dynamic trajectory analysis using ultra-fast EtherCat protocol

- Versatile machining with spindles and aggregates

- Comprehensive monitoring of key components

- Remote technical support

Dedicated materials

- Steel and soft metals: aluminum, brass, copper, bronze, etc.

- Composites: dibond, alucobond, etc.

- Plastics: polycarbonate, PVC, plexiglass, Teflon, polyamides, etc.

- Solid wood and wood-based panels: plywood, chipboard, MDF, OSB, etc.

- Extruded materials

Equipment options

- Tilt/rotary head

- Additional angular/rotational axes

- Angular aggregates

- Material positioning and correction via camera, laser, and measurement probes

- Revolver tool magazine

- Beams moved automatically or manually

- Vises moved automatically or manually

- Pneumatic clamping devices

- Tool cooling with oil mist or freezing nozzle

- Chip extraction foot operated automatically

- Integration with industrial robots

- Correction map

- Conveyor belt for chip removal

- CAD/CAM 3D software

Benefits of purchasing Seron machines

The advantages and capabilities of our devices are not all you will get by choosing to cooperate with us.

Ask for an offer or ask a question

Our advisors are at your disposal. Fill out the form below and contact us!