Description

Intuitive operation

Advanced control with a clear interface meeting the expectations of experienced users

Selected components

Machines are equipped only with the highest quality components, known and recognized on the market, guarantee reliability.

High dynamics

Top-class drive systems in cooperation with high-class controls guarantee high dynamics and precision of work.

Technical data

| Control system | Multi-axis real-time interpolator, with active trajectory forecasting, LAN communication, EtherCat, 2ms sampling time, optional RTCP tool end tracking, correction map |

|---|---|

| Working area | X 600 – 2500mm Y 900 – 6100 mm |

| Gate clearance and Z axis range | 100 – 700 mm |

| Drive system | Omron servo drives with EtherCat protocol, X, Y helical slats hardened ground in accuracy class 6, Z axis ball screw with accuracy class 5 |

| Linear bearing | Trapezoidal rails, Bosch Rexroth 25 |

| Travel speed | Up to 90 m/min |

| Acceleration | Up to 1G |

| Program resolution | Up to 0,0001mm |

| Positioning accuracy | 0,01 mm |

| Gate drive | double-sided master / slave with gate angle correction |

| Electrospindles | 2 kW to 18 kW powered by an inverter |

| Tool taper | ISO30 or HSK63 ER32 |

| Maximum speed of the electro-spindle | 24000 rpm (option 6 000, 40 000, 50 000) |

| Construction | Steel welded, ribbed, stress relieved, precision machined |

| Equipment options |

|

| Table type | T-slot: aluminum profiles, solid aluminum, solid steel; vacuum; hybrid, pneumatic clamping clamps |

Gallery

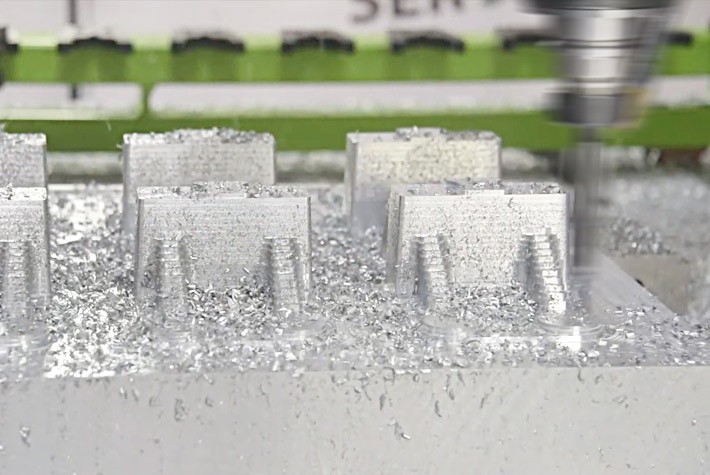

Uncompromising versatility

Expert series are high-class CNC machining centers manufactured in Poland. They have been designed in cooperation with demanding users of milling plotters and with the help of experts in the field of machine construction. Thanks to this, we have developed a series of machine tools that allow for fast, dynamic and quality work. These machine are dedicated to companies that focus on automation and minimization of production costs as well as increasing the efficiency of their plant. The transparent and at the same time advanced control system makes the device requirements of experienced and demanding operators, ensuring ease of use.

Expert series machines are built on the basis of a rigid welded, ribbed, steel structure, which is stress-relieved and machined from a single clamping on large-format machining centers. The machine in the basic configuration is equipped with AC servo drives coupled with the high-speed control system via the EtherCat protocol, which ensures fast and precise processing and active tracking of the machine trajectory in real time, minimizing lagging error.

Construction

The steel, welded and ribbed structure is characterized by the highest parameters, ensuring precise processing at high speeds and dynamics of movements. The bed and the running elements are subjected to the process of stress relief and machining on large-format milling centers, which ensures long-term stability and dimensional precision of the machine. Learn more about the construction »

Control

Industrial, professional CNC control integrated with the LAN network allows for active communication with key components. The EtherCat protocol used enables ultra-fast, two-way communication with a sampling time of less than 1 ms. The multi-axis real-time interpolator actively forecasts the trajectory of movements also in HPM and HSM modes minimizes lagging error resulting in dynamic, smooth and precise operation. Integrated CAD / CAM environment allowing for easy editing of designs directly on the control unit increases flexibility in operation. The structure of the G-code allows you to automate the cycles and operations performed according to individual needs. Learn more about control »

Basic features of the Expert series

- modern real-time control system

- dynamic trajectory analysis

- high-speed EtherCat communication protocol

- rigid structure combined with top-class components

- remote technical support

Dedicated materials

- steel and soft metals: aluminum, brass, copper, bronze etc.

- composites: dibond, alucobond, etc.

- plastics: polycarbonate, PVC, plexiglass, teflon, polyamides, gambit, rubber, etc.

- solid wood and wood-based panels: plywood, chipboards, MDF, OSB, etc.

- paper, cardboard, foil, etc.

- foams, extruded materials, etc.

- leather, textiles etc.

Equipment options

- positioning and correction of the material by a camera, laser, measuring probe

- linear, turret tool magazine

- cooling the tool with mist, chilled air

- 3D laser or touch scanner

- positioning bases

- additional angular / rotary axes

- drilling units, angular

- active oscillating knife, roller knife, drag knife, creaser, marker pen

- pneumatic clamping clamps

- chip extraction installation

The benefits of buying Seron machines

The advantages and capabilities of our devices are not all that you will get by choosing to work with us.

Ask for an offer

Our advisers are at your disposal. Fill out the form below and contact us!