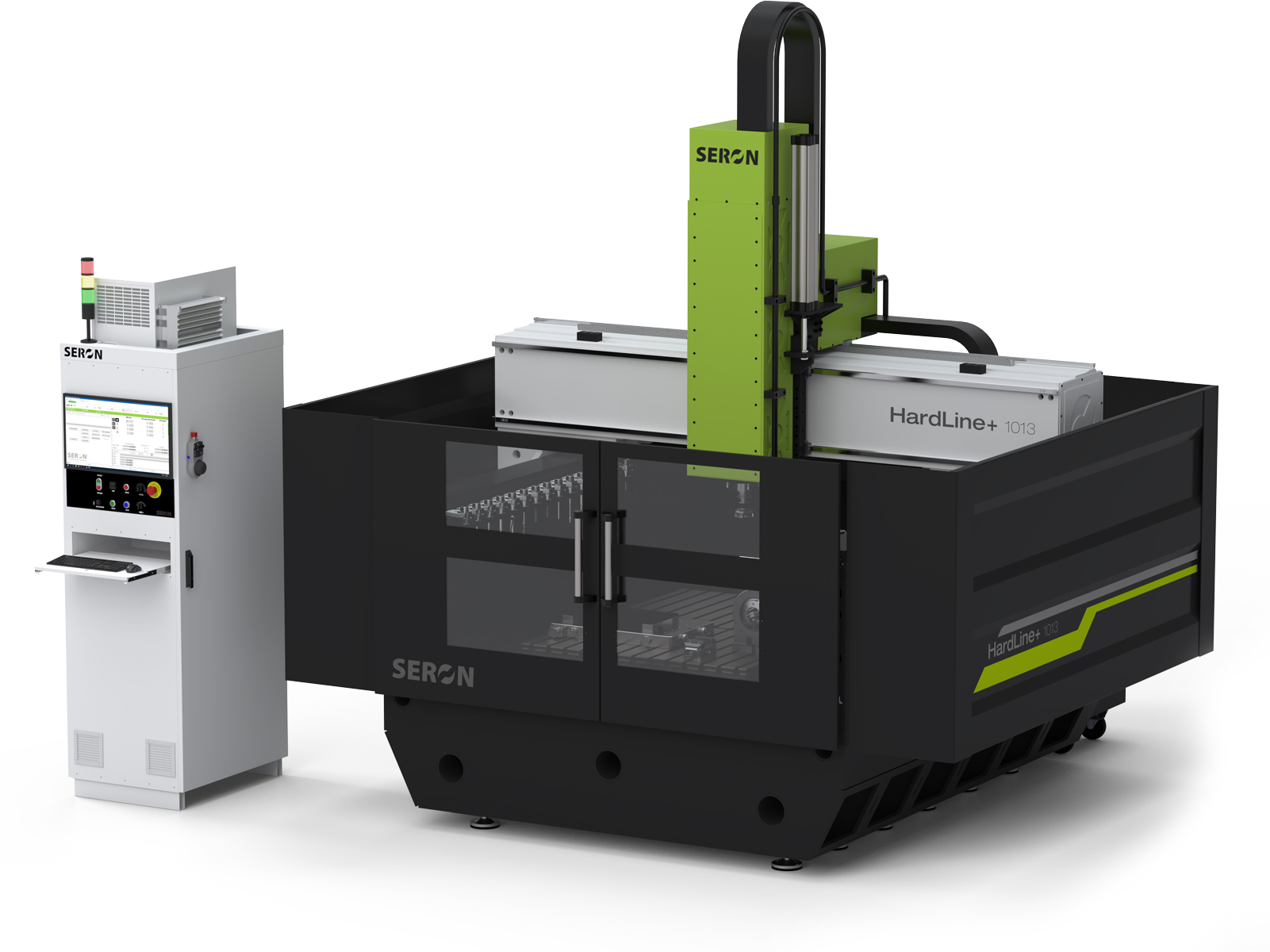

Description

Highest precision

Full repeatability of milling plotters and accuracy of manufactured details guaranteed by a solid structure and high-class control.

Functional control

Industrial control system for the comprehensive management of the machine and its key components.

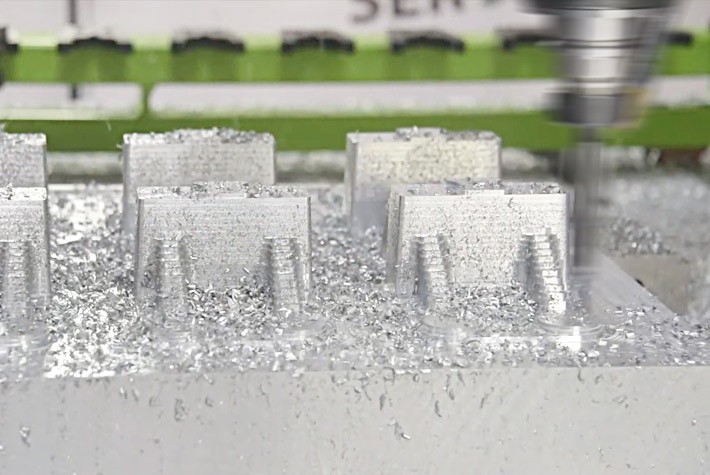

High efficiency

The solid structure allows for aggressive machining while maintaining the precision of the details and their repeatability.

Application examples

Technical data

| Control system | multi-axis real-time interpolator with active forecasting trajectory, LAN communication, EtherCat, sampling time below 1 ms, RTCP, remote service access |

|---|---|

| Working field | X: 600 – 2000 mm; Y: 900-3000 mm (other fields on request) |

| Z axis clearance | to 700 mm (above on request) |

| Drive system | Bosch Rexroth drives, Bosch Rexroth measuring scales. Helical strips hardened, ground, accuracy class 6, Z axis, ball screw class accuracy 5 |

| Linear bearings | trapezoidal rails, Y axis, quadruple guide size 25, triple X axis guide 25 and Z triple guide size 25 |

| Travel speed | to 25 m/min |

| Acceleration | to 1G |

| Software resolution | to 0,0001mm |

| Positioning accuracy | 0,01 mm |

| Gate drive | double-sided master/slave with gate angle correction |

| Electrospindles | to 25 kW |

| Tool cone | HSK63, ISO40 |

| Maximum electrospindle revolutions | 24000, 13000, 6000 rpm |

| Construction | welded steel |

| Type of table | T-shaped steel, aluminum |

| Equipment options |

|

Gallery

Construction

Machines from the HardLine+ series have a massive structure, which guarantees lasting dimensional precision and machine stability. The steel, welded and ribbed structure is adapted to high-efficiency and precise machining of demanding materials. Kinematic properties ensure high quality of processed surfaces. Stress relief and machining processes from a single fixture on large-format milling centers ensure the lasting precision of the presented machine. The table is made of high-quality steel and allows for mechanical mounting, which ensures stabilization of the elements, which is especially important when processing details. The machine is standardly equipped with measuring rulers, ensuring positioning accuracy of 0.0005 mm.

Full construction of the machine

Additionally, the HardLine+ series includes a full machine structure. The construction combined with a solid construction makes the HardLine+ Machining Center ready to meet the most demanding working conditions, while ensuring safety and maintaining the highest quality of machining. This solution is another step towards a comprehensive approach to efficiency, durability and precision in the machining industry. Find out more about the structure »

Control

Milling plotters from the HardLine+ series are equipped with an industrial control system. The EtherCat protocol enables fast two-way communication with key components, and a multi-axis, ultra-fast real-time interpolator minimizes tracking error. The integrated CAD/CAM environment facilitates the operator’s work by enabling file editing directly on the control unit. The use of absolute rulers eliminates the need to perform axis reference movement, which increases precision and saves time. Additionally, remote service access allows you to monitor and maintain the machine at the highest level of performance, which makes it not only a work tool, but also an investment in long-term production success. Learn more about controls »

Basic Features of the Hardline+ Series

- Modern real-time control system

- Dynamic trajectory analysis with EtherCat protocol

- High vibration damping coefficient

- Efficient machining of demanding materials

- Precision table made of solid material

- Effective tool cooling

- Rich equipment

- Remote technical support

Dedicated Materials

- Metals

- Composites (dibond, alucobond, etc.)

- Plastics: polycarbonate, PVC, plexiglass, rubber, Teflon, polyamides, etc.

- Solid wood, plywood, particle boards, MDF, OSB

Benefits of purchasing Seron machines

The advantages and capabilities of our devices are not all you will get by choosing to cooperate with us.

Ask for an offer or ask a question

Our advisors are at your disposal. Fill out the form below and contact us!