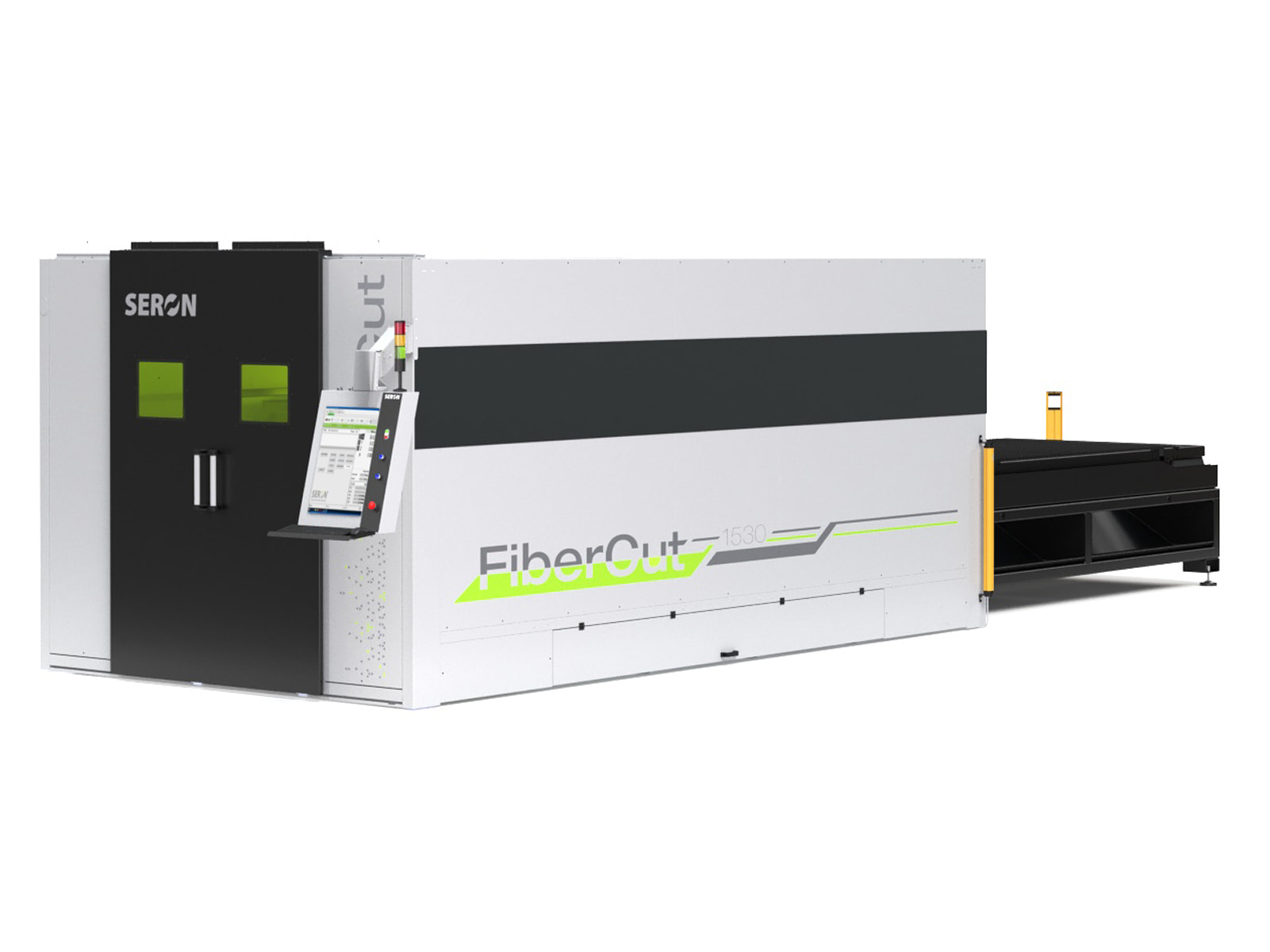

Description

Instant nesting

Selected components based on a well-thought-out design guarantee instant and immediate sheet metal nesting.

Perfect precision

The Fiber Cut machine guarantees a stable cutting process without the need for maintenance, replacement of consumables, mirrors or accompanying elements such as turbine pumps. It takes up much less space compared to other solutions.

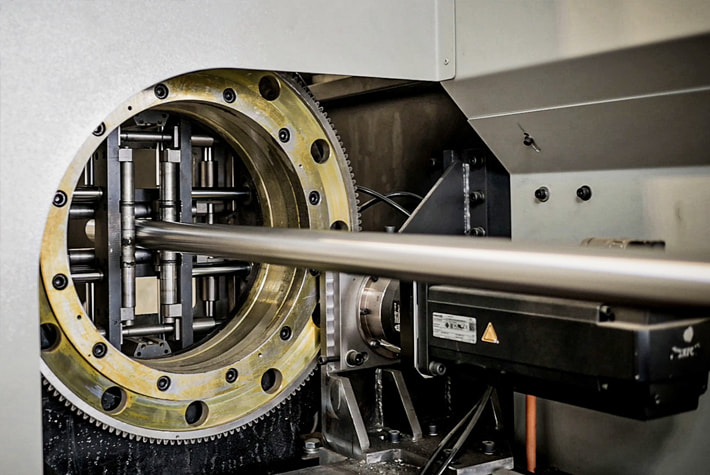

Cutting pipes and profiles

By equipping the machine with a rotator, you can laser process pipes, profiles and open sections.

Energy saving

Greater efficiency in relation to CO2 sources, resulting in lower electricity consumption by about 70%.

Low operating costs

Minimum number of consumables and simple maintenance.

Perfection on all sides

Take a virtual walk around the machine. Grab a 360 ° photo and rotate the visualization to see the elements of interest in detail.

Application examples

Technical data

| Control system | Bosch Rexroth, real-time interpolator with active trajectory forecasting, Sercos communication protocol, remote service access, touch screen, visual trajectory cutting, built-in macro library (shapes), adjustments speed, operating mode of the laser cutting system, ability to transfer files via LAN. |

|---|---|

| Working field | X: 1550, 2050 mm; Y: 3050, 4050, 6050 mm |

| Profile length | to 6 000 mm / 12 000 option |

| Pipe diameter | to 170 mm option to 240 mm |

| Max speed | to 210 m/min |

| Powers | 1–20 kW |

| Acceleration | to 2G |

| Positioning repeatability | 0,01 mm |

| Automatic height adjustment | yes |

| Variable head focal length (zoom) | autofocus |

| Table load capacity | 265 kg/m2 |

| Equipment options |

|

Gallery

Innovative construction

Designed based on proven design and technical solutions, the FRC series was created for entrepreneurs requiring compact solutions. These cutting machines allow for multifunctional production with one device while saving space in production halls.

The machine’s structure has been designed to work with pipes with a diameter of 20 mm to 170 mm and square profiles up to 170 mm, length 6000 mm and weight up to 250 kg.

The rotator enables cutting and drilling pipes and profiles using innovative laser technology. FRC series devices are characterized by high accuracy, repeatability and enable the positioning of details relative to each other. Thanks to this, these cutters are perfect for aligning details in relation to each other in welding processes and in plants with robotic welding stations.

Find out more about the structure »

Piercing efficiency

Another innovation of the presented machine is the use of elements that automatically focus the laser beam with ultrafast sensors. The dynamic operation of this solution allows the material’s piercing time to be reduced by two times. During the process of piercing sheet metal, a laser beam with a larger diameter is needed than during the cutting itself. The use of a double, dynamic focusing system allows you to maintain the distance between the nozzle blowing the accompanying gas and the material at the working distance. The introduction of such a solution increases the efficiency of blowing spoil. Meanwhile, the movable lens inside the cutting head actively adjusts the focal length to the currently set process, smoothly switching from multi-stage piercing mode to cutting mode.

Thanks to the system used, we are able to significantly shorten the sheet processing time. Assuming a number of up to 50 punctures, we can gain up to 120 seconds, which gives up to 10% savings in relation to the entire process.

Work efficiency

FiberCut fiber optic cutting machines are standardly equipped with a table replacement system, which significantly simplifies the replacement and loading of boards and shortens the overall project implementation time, and thus allows maximum optimization of production costs. While the operator is loading and unloading, the machine cuts another sheet, which results in 100% efficiency in using the machine’s capabilities. Pallet replacement time is only 10 seconds.

High precision

FRC series machines are characterized by high precision and accuracy even when using high speeds and cutting complex shapes. These cutting machines successfully replace other profile cutting devices in production processes. FiberCut laser cutting machines dedicated to cutting pipes and profiles are equipped with, among others: the latest generation of fiber optic sources and modern laser heads with the Auto-Focus function.

Control

An advanced control system with a built-in nesting option allows you to optimize and control production costs. The standard equipment also includes touch control. The user interface is simple, intuitive and allows you to display machining processes in real time.

Industry 4.0

The machine fits perfectly into the concept of modern industry thanks to its intuitive, modern real-time control system with dynamic trajectory analysis and a reliable Ethernet connection, which enables comprehensive management of the machine park. It allows for remote analysis of the machine’s condition and control of operating parameters in order to obtain the best possible machining effect. The control is equipped with a number of advanced functions such as auto-detection of the sheet, position angle correction, autonesting, material database and parameter library available from the operator level. These functionalities affect the high efficiency of the machine, saving time and materials. Such an innovative solution will work well for entrepreneurs who emphasize innovative management concepts and increasing production efficiency.

Fiber lasers are equipped with dynamic control of the height of the laser head above the material with an accuracy of 0.005 mm and a shielding gas system, which significantly affects the quality and speed of cutting. The CNC control system is both intuitive and very user-friendly.

Energy saving

The undoubted advantage of fiber laser cutters over CO2 or YAG lasers is the significant simplification of the optics, the lack of mirrors transmitting the laser beam (transmitted inside the fiber to the laser head), which allows transmission losses to be reduced to a minimum. Another significant advantage of the Fiber laser source is its higher efficiency, up to 7 times higher than CO2 laser sources, resulting in lower electricity consumption by approximately 70%. By sending the laser beam to the head via optical fiber with virtually no losses and concentrating the energy to a high density on a very small diameter, the cutting speed of especially thin sheets is several times higher than when using a CO2 laser, the consumption of process gases is also much lower due to the lower impact of heat. . The drives used also allow energy recovery from engine braking and its reuse.

Key Features of the Fiber Cut Fiber Laser Cutter:

- High durability of key components

- Optimized optics minimize transmission losses

- Modern real-time control system with dynamic trajectory analysis and Ethernet connectivity

- Energy-efficient technology

- Ergonomic protective enclosure meeting legal requirements

- Monitoring of key components

- Autofocus

- Automatic cooling system ensuring stable operation

- Customizable work area

- Remote technical support

Dedicated Materials

The fiber laser cutter ensures precise cutting of:

- Carbon steel

- Stainless steel

- Aluminum

- Brass

- Copper

Expansion Options

The machine’s design allows for significant expansion, such as adding a tube and profile rotator, sheet metal storage, sheet metal scrap management, and more.

Benefits of purchasing Seron machines

The advantages and capabilities of our devices are not all you will get by choosing to cooperate with us.

Ask for an offer or ask a question

Our advisors are at your disposal. Fill out the form below and contact us!