Description

A wide range of applications

Unlimited working area and a large range of sheet metal thicknesses

Functional controls

Intuitive and easy to use controls with a wide range of possibilities.

Selected components

Machines are equipped only with the highest quality components, known and recognized on the market, guarantee reliability.

Technical data

| Working area |

X: 1550, 2050 mm; Y: 3050, 4050, 6050 mm |

|---|---|

| gate clearance | up to 500 |

| Speed of travel | up to 50 m/min |

| Drivers | x ,Y racls, z ball screw |

| Bearing | Modular extraction, separated by the runway |

| Type of table | up to 80 m/min |

| Additional options | ꞏrotary axis (range 50 – 650mm), ꞏ extended portal, ꞏ module for drilling, chamfering, tapping, separate work zones |

Gallery

Efficient and flexible

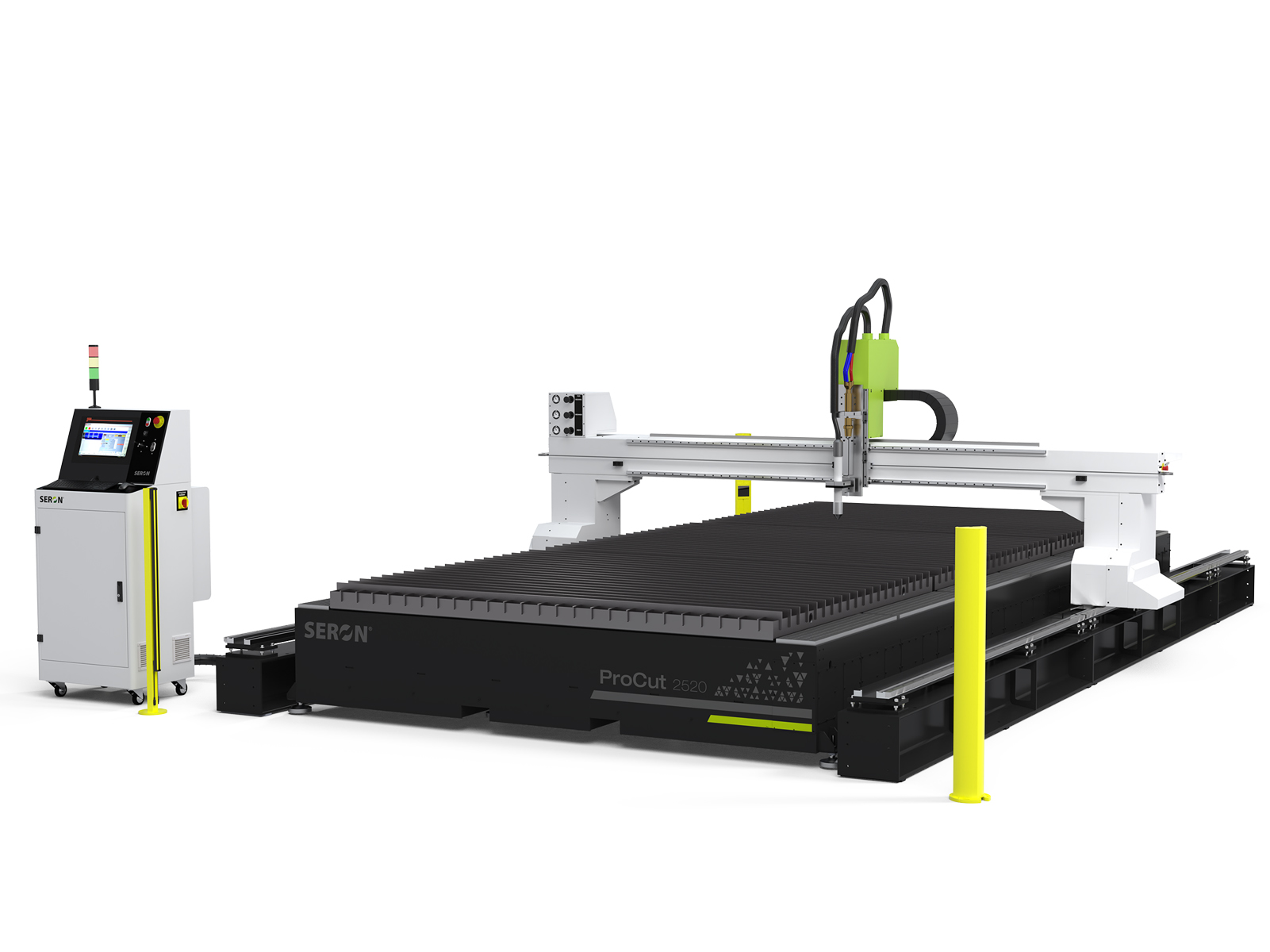

Seron portal cutters are industrial solutions for metal cutting, characterized by the use of several burners in their construction. The DualCut portal cutter is equipped with an innovative gas-oxygen burner that is perfect for cutting steel with thicknesses from 3 to even 300 mm, and a plasma torch that works well for universal processing of various types of metals and different thicknesses.

Construction

The steel, welded and ribbed structure is characterized by the highest parameters, ensuring precise processing at high speeds and dynamics of movements. The bed and the running elements are subjected to the process of stress relief and machining on large-format milling centers, which ensures long-term stability and dimensional precision of the machine. Learn more about the construction»

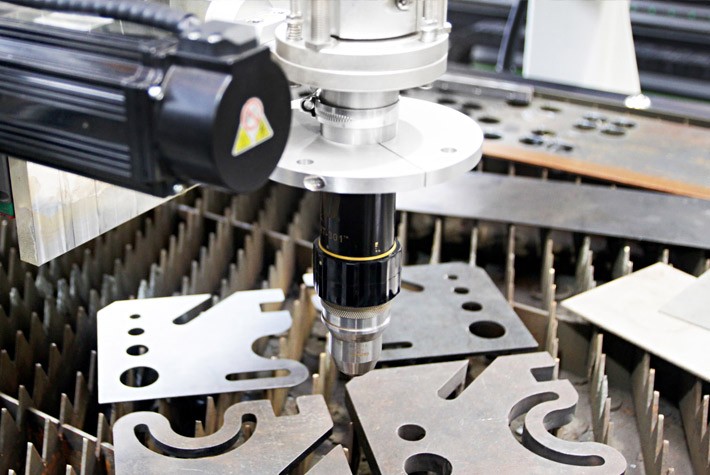

Controls

The professional world-class control that has been implemented in our cutters is ergonomic and functional. It uses a protocol that enables two-way communication with components, which allows for monitoring and active correction of their parameters as well as ultra-fast setting and control of the drive position. It has many built-in functions to optimize machining processes, reducing production costs. The control of the device is intuitive and simple, and also fully compatible with CAD / CAM programs. The built-in internal memory allows you to save the generated projects, which is a great help when working with the machine. Learn more about controls »

Basic features of the oxygen / plasma cutter

- precise and repeatable cutting of steel

- steel welded structure combined with the highest quality components

- portal structure, track is separated from the work table

- significantly lower operating costs compared to water cutting

- modular design allowing any working size

- possibility of cutting with both plasma and gas

Dedicated materials

- black steel

- stainless steel

- aluminum

Equipment options

- sectional extraction table with an exchangeable grate with a load capacity of up to 2500 kg / m2

- laser torch position indicator

- Rotary axis for processing pipes and profiles with a working area length

- additional oxygen or plasma torch

- mobile pallet for easy loading and unloading

- drilling module

- tapping module

- marking module

The benefits of buying Seron machines

The advantages and capabilities of our devices are not all that you will get by choosing to work with us

Ask for na offer

Our advisers are at your disposal. Fill out the form below and contact us!