Description

Intuitive operation

Machine are equipped only with the highest quality components, known and recognized on the market, guarantee reliability.

Selected components

Machine are equipped only with the highest quality components, known and recognized on the market, guarantee reliability.

Versatility

Wide range of machinable materials in a solution dedicated to enterprises with a diversified production profile.

Perfection on all sides

Take a virtual walk around the machine. Grab a 360 ° photo and rotate the visualization to see the elements of interest in detail.

Technical data

| Control system | Multi-axis real-time interpolator, with active trajectory prediction, LAN communication, EtherCat, 4 ms sampling time |

|---|---|

| Working area | X 2100mm Y 3100 mm |

| Ground clearance and Z axis range | 300mm |

| Drive system | Servo drives, X, Y, Z helical strips |

| Linear bearings | Trapezoidal rails, trolleys |

| Travel speed | to 40 m/min |

| Software resolution | to 0,0001 mm |

| Positioning accuracy | 0,02 mm |

| Gate drive | double-sided master/slave with gate angle correction |

| Electrospindles | up to 7.5 kW powered by an inverter |

| Tool mounting | ISO30 lub HSK63 ER32 |

| Maximum electrospindle revolutions | 24000 obr/min (opcja 6 000, 40 000, 50 000) |

| Design | Steel welded, annealed, precision machined |

| Equipment options |

|

| Table type: | T-slot; aluminum profiles; vacuum; hybrid |

Gallery

Ergonomic and versatile

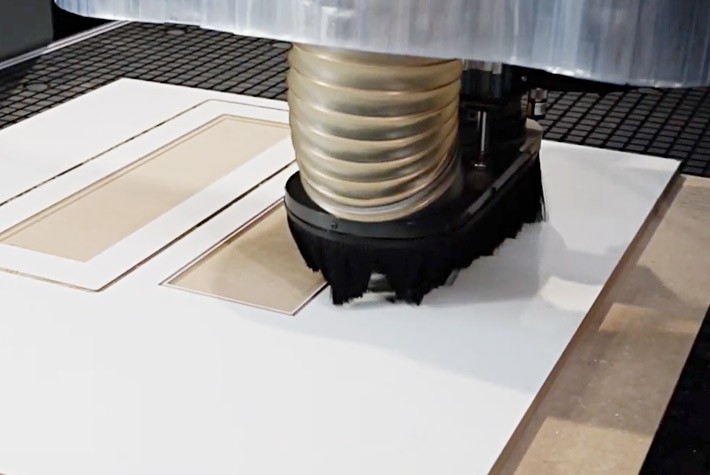

Nest series CNC milling plotters are modern and universal machines manufactured in Poland. They are designed for precise machining of a wide range of materials. The machine’s structure is made of high-quality welded steel, then annealed and precisely processed on large-format machining centers. The structural elements are ribbed, which ensures high stiffness and resistance to machining resistance. The drives used in each axis allow for high speeds and dynamic work. Bearing using trapezoidal rails with trolleys guarantees precision and reliability.

Design

The rigid steel structure with high kinematic parameters allows for efficient work while maintaining high machining precision. Structural elements are subjected to annealing processes and then processed in one mounting on large-format machining centers. This ensures long-term stability and dimensional precision of the machine. Find out more about the structure »

Control

The machine is based on industrial professional CNC control with a multi-axis real-time interpolator that actively predicts the trajectory of movements. The EtherCat protocol used with a sampling time of less than 1 ms allows for instant, two-way communication with key machine tool components. The integrated CAD/CAM environment enables simple editing directly on the control unit, giving the operator greater flexibility. Connectivity to the LAN network allows the machine to be implemented into a machine park managed in the Industry 4.0 concept. Learn more about controls »

Basic features of the Nest series

- functional real-time control system

- dynamic trajectory analysis

- rigid steel structure

- selected components

- intuitive operation

- remote technical support

Dedicated materials

- composites (dibond, alucobond, etc.)

- plastics: polycarbonate, PVC, plexiglass, rubber, Teflon, polyamides, etc.

- engraving laminates,

- solid wood, plywood, chipboards, MDF, OSB,

- foams, extruded materials, etc.

Equipment options

- T-groove table, vacuum table, hybrid table

- scanner

- positioning databases

- tool cooling in the form of cooling mist

- chip extraction installation

- monitoring key components

Benefits of purchasing Seron machines

The advantages and capabilities of our devices are not all you will get by choosing to cooperate with us.

Ask for an offer or ask a question

Our advisors are at your disposal. Fill out the form below and contact us!