CNC milling machine supply the machine parks of most production factories operating in the automotive industry. CNC machines allow enterprises to remain competitive and grow at an impressive pace. One of such companies is located in Wojnicz in the Malopolska Voivodeship. Mr. Piotr Kardaś, the owner of Maxton Design, a manufacturer of optical tuning accessories, appreciated by thousands of customers from all over the world, has been relying on Seron machines for many years.

What and how long has Maxton Design been doing?

We manufacture and sell accessories for passenger cars, such as: spoilers, splitters, bumpers. We have been operating since 2006, but on a larger scale since 2016.

Your website is in English by default. Is your customers mainly come from abroad?

Foreign clients predominate. We export as much as 95% of our products. We ship them literally all over the world. Recently, for example, we have been carrying out orders for a client from Reunion – a small island near Madagascar. Less than 5% stay in Poland. Although it seems to be a small percentage, from our point of view it is still a very good result, and the number of domestic customers is still growing.

Are you most selling unit orders or rather serial orders?

These are various orders, some individual for individual customers, some serial, often ordered for resale.

You said most of the products are exported. So I expect that most of the customers do not come to the measurements in their car then. How does the design of such an element look like?

If we get a request for car accessories that we dont have in our library, we search for such a model in the near side. On our Facebook fanpage, sometimes appears a question about a specific model. Owners of such cars report to us. Then we scan the vehicle, and in return for making it available, the owner receives a package of accessories for his car, and we can fulfill the order for the end customer. The same is true when we want to introduce an element to our offer.

When did you meet the Seron company and what machine you boughts from our offer?

We met Seron in 2016. When we found Seron, the price seemed very attractive, which caught our attention. The company made a very good impression on us, we talked very well, and we took a little risk. We didn’t know much about this brand. However, we immediately reached for the highest Professional series (currently PRO+). We are very pleased with the choice. The machine works in a two-shift system. Nothing disturbing has happened to it since the installation. The website also works very well. Therefore, the choice was also simple with the next machine.

What elements do you make on it? What materials?

We produce molds for our products on milling machines. We make them from wood, prolab, modeling plates, sometimes aluminum.

You have been investing in CNC machines in over 5 years. How are these machines different from each other?

The main, the biggest difference is the controls. More modern and functional. We also see that some components are replaced with new ones with higher parameters. Some solutions are improved compared to the previous ones, so all changes are a plus.

You bought your first machine in 2016. How many Seron machines do you currently use and how do you rate the cooperation with Seron?

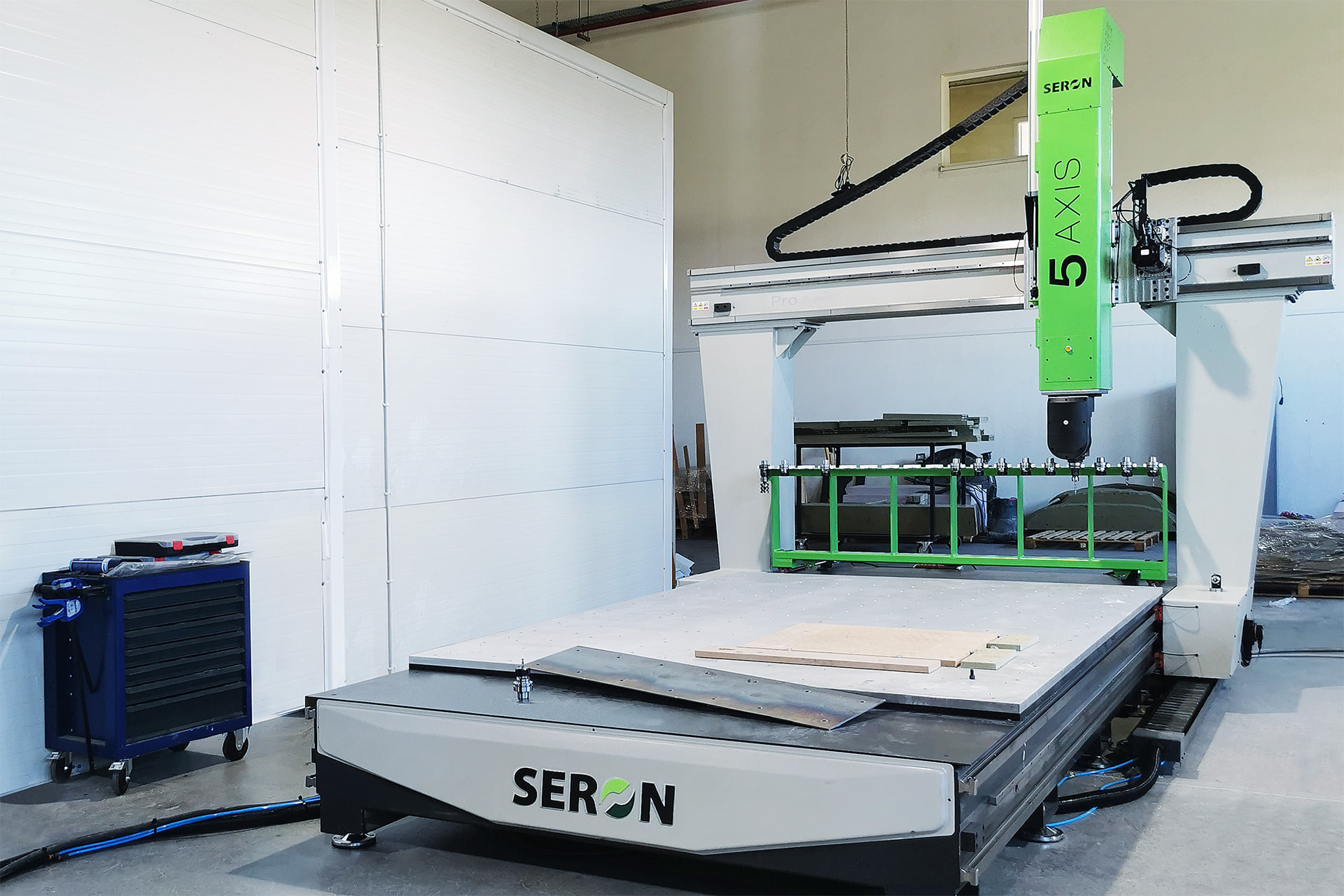

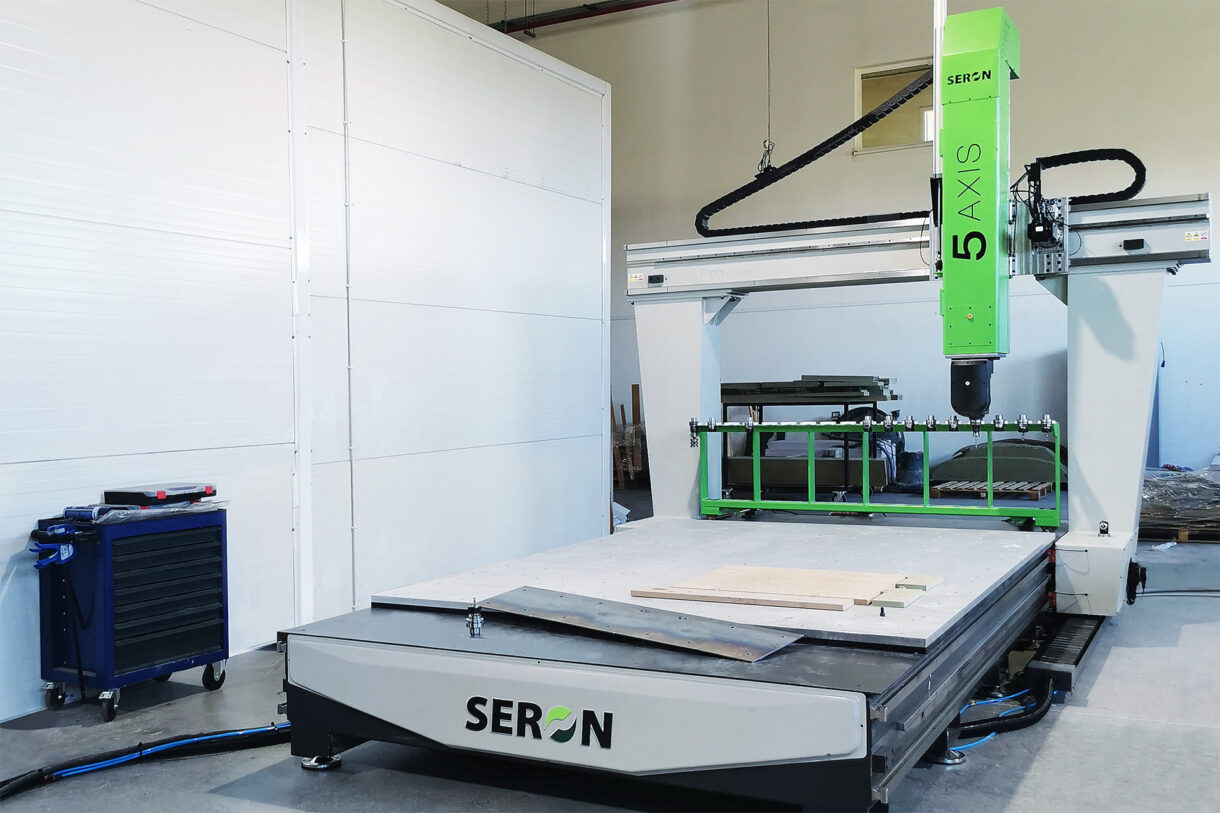

I was involved in the purchase of a total of 8 machines, 6 of which are used in the production of accessories at Maxton. How do I rate them? The answer is hidden under subsequent orders. The last one was installed in September 2021. This time the machine park was supplied with a 5-axis machining center. I have no objections to cooperation with Seron. Even in stressful or nervous situations, as it used to be, I set your method of solving problems as an example for my employees. Both the commercial, service and technical and professional.

What are your goals for Maxton?

Recently, I am more and more interested in the topic of the company’s development towards Industry 4.0. I would like to introduce more automation to the production line, managed by artificial intelligence in order to produce faster and better. One revolution is already behind us when we switched from manual production to the more automated one. The work of modelers was replaced by the work of a 3D scanner, good graphics and milling machines. It was a breakthrough in the development of our company. I expect that the Industry 4.0 management idea, for which we are preparing to implement, will also be a milestone in the development of our products.

We invite you to take a look at the client’s website: https://maxtondesign.pl/ and Facebook profile Maxton Design

Maxton was adviced by

Krystian Rydz